About us

design engineer master mould manufacture

The two directors have a combined total of over sixty years of experience working on automotive and motorsports composite projects in the above five disciplines.

This journey began following the completion of automotive engineering degrees at the

University of Hertfordshire in 1988. At this time everything was done by hand and some very steep learning curves were climbed. In a few short years one hundred and forty vehicles with a

glassfibre reinforced polyester monocoque had been produced. (1994)

Following an introduction to the directors of Prodrive the first of many carbon fibre WRC mirrors

was produced using pre-preg carbon. (1995)

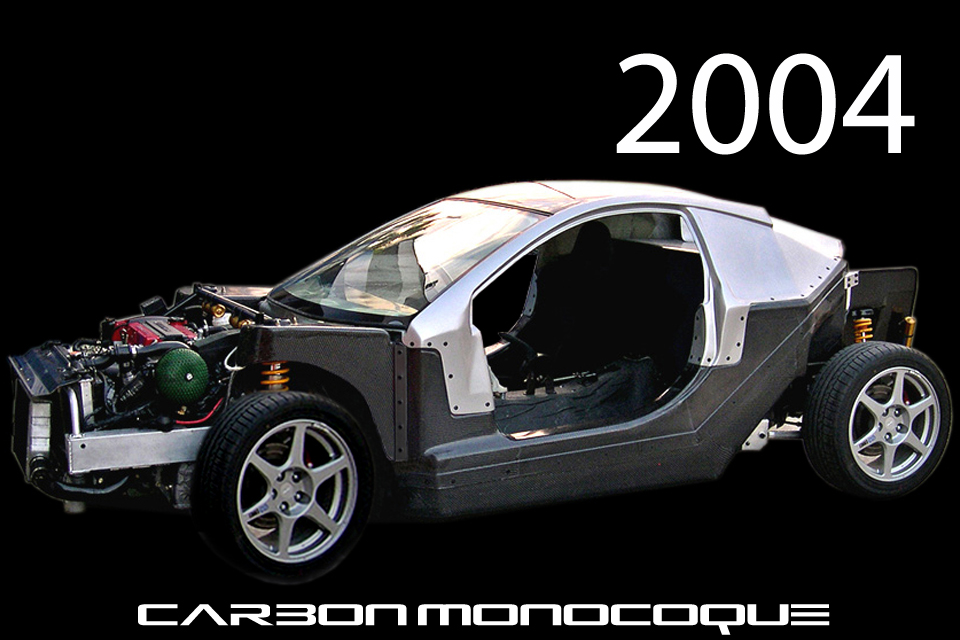

Attentions focused on applying the superior mechanical properties offered by carbonfibre/epoxy composites

to a vehicle monocoque. An autoclave large enough for car sized assemblies was ruled out on cost.

Vacuum Infusion was considered the only option, and a carbonfibre/epoxy monocoque was designed and manufactured around a set of Mitsubishi Evo 6 running gear. (2004)

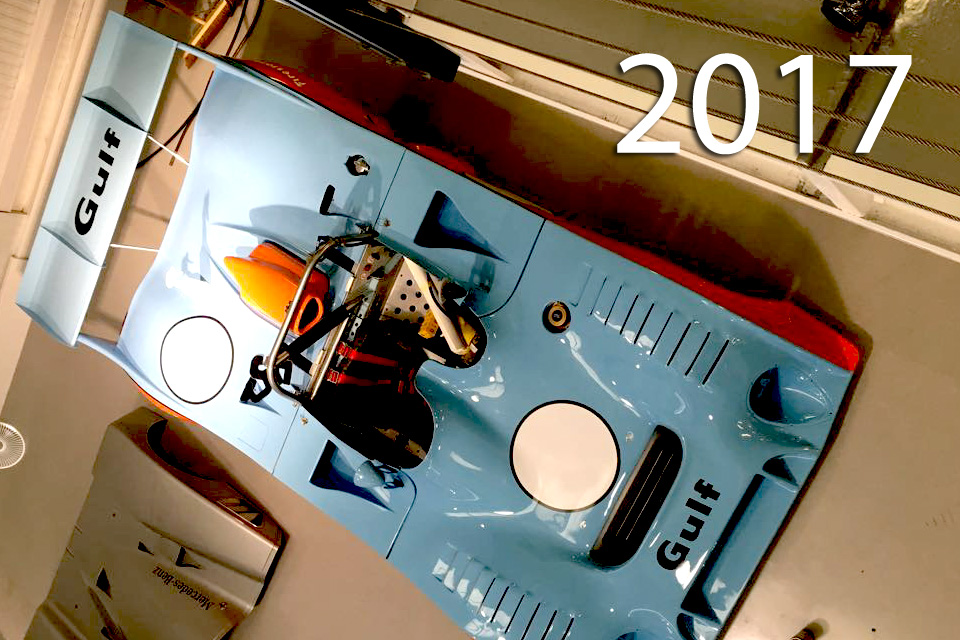

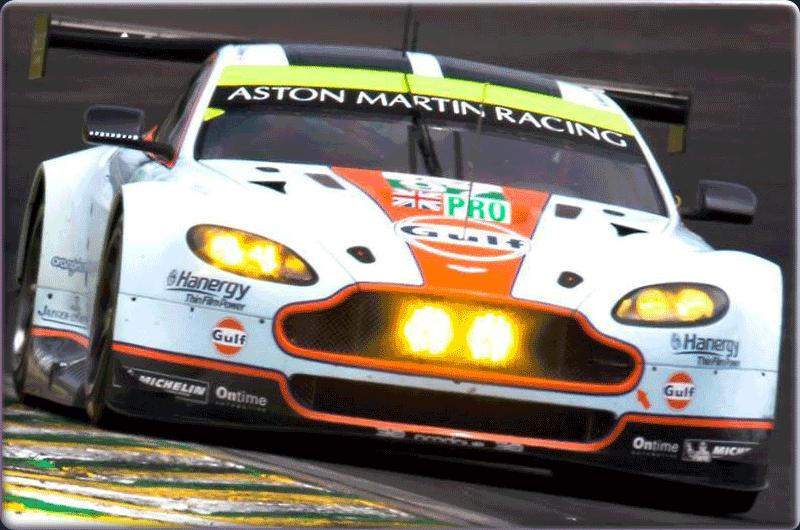

The knowledge accrued during this project was used to start producing parts for Prodrive GpN

Subaru rallycars, and then subsequently WRC (Mini), GTE (Aston Martin), GT3 (Nissan GTR),

SCRC (Golf) and now WRX (Megane). (2008-2018)

Today XWorks employs nine people, in addition to the two directors, operating in five hundred square

metres of space. Five ovens capable of accommodating car sized panels are available for curing

purposes along with a paint booth, a three axis CNC milling machine and a six axis three metre

reach robot. Projects are almost exclusively CAD based now and we have well in excess of

ten thousand hours of CAD experience specifically working with composites in the

automotive and motorsports fields.

Over the past thirty years a huge amount of knowledge has been acquired in the design of composite

parts for use in these applications. Prioritising the often conflicting parameters of component design

with an appreciation of the costs involved to achieve the 'solution'....

Milestones