Vacuum Infusion

vacuum infusion - simple principle

Dry fabric is placed in a mould and held under a vacuum.

Resin is then injected through the fabric driven by atmospheric pressure.

When the resin is cured, the part is demoulded.

Certain aspects of the process require careful consideration

when designing components to achieve consistent quality

and performance over a production run.

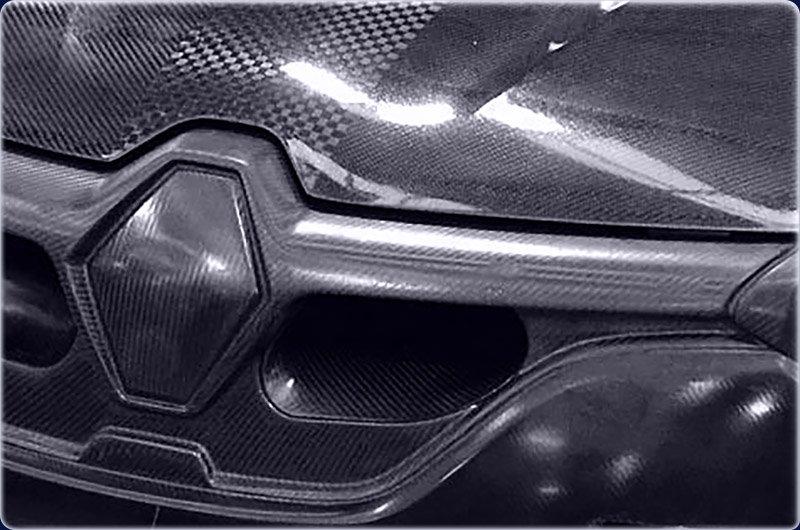

a typical vacuum infusion arrangement

a simple demonstration

VACUUM INFUSION - THE ADVANTAGES

HIGH PERFORMANCE

Very high fibre fractions are achievable – in conjunction with high performance fabrics and resins this enables the production of parts that approach the performance of pre-preg items. In some instances VI parts can outperform

similar pre-preg parts because of the easier availability of tailored performance resins & fabrics.

COST EFFECTIVE

Low processing temperatures allow the use of cheap tooling – this is particularly significant for short production runs where the cost of tooling is a major part of the cost of the finished item. High temperature performance of finished parts can still be achieved with post de-mould curing.

MATERIALS FLEXIBILITY

Using dry fabrics provides a huge choice of 'off the shelf' materials when designing layups. Similarly a large range of resins with different specific properties are available 'off the shelf'.

SURFACE FINISH

VI delivers a microscopically thin unbroken resin film on the mould facing surface of the part giving a very high quality of finish – ideal for carbon car parts.

MAINTAINING FINISH OVER A PRODUCTION RUN

VI is very kind to moulds maintaining a high standard of finish over their lifetime.

Mould life is greatly extended over traditional pre-preg processes.

PROCESSING HEAVY LAYUPS

There is no top limit to the weight of laminate thickness that can be layed up and infused in a single shot – this is a strong advantage for large mouldings (de-bulking after every few layers is not required).

PROCESSING CORED LAYUPS

Cored layups can be processed in a single shot.